|

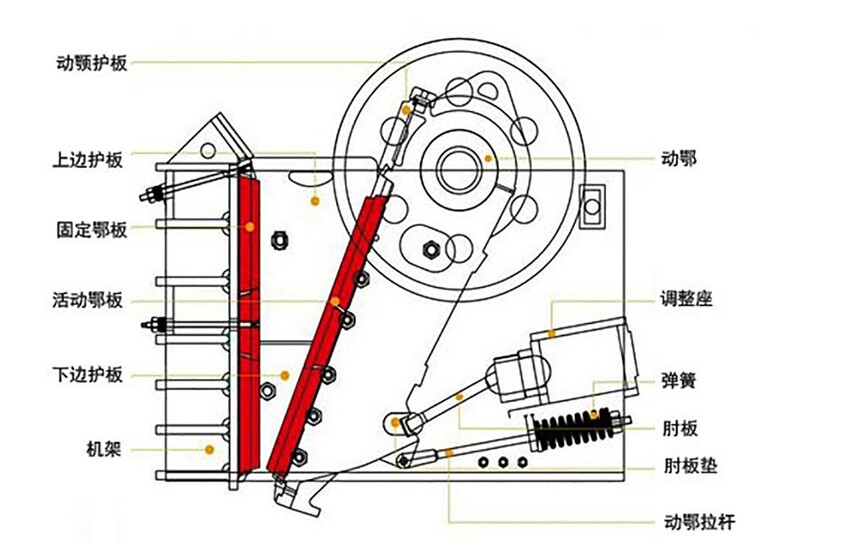

Measures to reduce the wear of jaw plates in jaw crushersWhen the jaw crusher is in operation, the movable jaw plate performs periodic reciprocating motion on the fixed jaw plate. When approaching, the material is crushed by compression, splitting, and impact between the two jaw plates; When leaving, the crushed material is discharged from the discharge port by gravity. Therefore, the jaw plate is one of the easily worn parts of the jaw crusher. How can we reduce the wear of the jaw plate of the jaw crusher?

Choose materials with strong wear resistance. When purchasing a jaw crusher or replacing the jaw plate, it is necessary to choose a jaw plate made of materials with high hardness, strong toughness, and good wear resistance.

Pay attention to the tightness of the jaw plate during installation. It is essential to fix firmly during installation. The jaw plate can be a toothed jaw plate. If necessary, a layer of plastic material can be placed between the jaw plate and the jaw head to firmly fix the jaw plate on the jaw head, ensuring smooth contact between the jaw plates of the jaw crusher and reducing friction.

Control the particle size of the feed material. Generally speaking, the feed particle size of the jaw crusher should be controlled within 85% of the maximum size of the feed inlet to avoid damage or excessive wear of the jaw plate caused by oversized stones, ensuring the crushing effect and efficiency.

Conduct random inspections on materials. Due to the significant impact of factors such as material composition, hardness, humidity, and mud content on the performance of the jaw plate, it is necessary to check for foreign objects or materials with high hardness in the material before entering the crushing chamber. If any foreign objects are found, they should be removed or the parameters of the crusher should be adjusted for materials with high hardness to meet the requirements of crushing the material. |