|

How to Choose an Appropriate CrusherBefore customers select crushing equipment, they should first determine the crushing force application method by adopting the corresponding force application approach based on the material properties of the particles, the crushed products, and the requirements for particle size. Only then can they confirm the model of the crushing equipment. The specific selection methods are as follows.

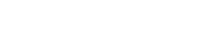

1.For hard materials with large or medium particle sizes, crushing methods such as compression crushing and impact crushing are generally used. Examples of applicable equipment include jaw crushers and toothed roll crushers.

2.For materials with high abrasiveness, compression crushing is mainly adopted, and the surface of the crushing tools should be smooth.

3.For materials with low abrasiveness, impact crushing, striking crushing, and grinding are applicable, and the crushing tools should be equipped with sharp teeth.

1. For hard materials with small particle sizes, compression crushing, impact crushing, and grinding are usually used. The surface of the crushing tools is smooth without teeth, such as double-roll crushers.

2. For tough materials, shearing or rapid striking methods are generally adopted, with hammer crushers being a typical example.

3. For powdery or muddy materials, grinding, impact crushing, or compression crushing are suitable options, such as ball mills.

4. For multi-component materials, selective crushing under impact force is recommended; alternatively, a combination of multiple force fields can be used.

In addition to the above factors, the moisture content of the material, the degree of ore dissociation, and the climate conditions where the ore is located will also affect the selection of ore crushing equipment. |