|

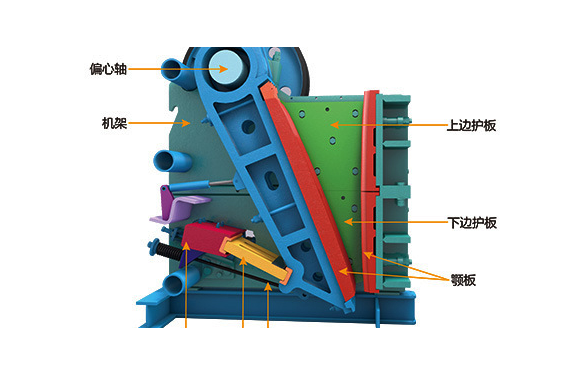

Common Problems in the Operation of Marble Sand Making MachinesMarble is an important building material and industrial material. Natural marble cannot be used directly; it needs to be processed and refined using relevant mining machinery and equipment. The more commonly used "shaping" tool is the marble sand making machine.

It should be reminded here that the sand making machine may encounter the following problems: 1. Excessive Vibration Amplitude of the Marble Sand Making Machine The marble sand making machine should operate relatively stably during its running period. Although marble materials have a relatively significant impact on the equipment, the marble sand making machines produced currently are capable of withstanding the strong impact of such materials. However, the excessive vibration amplitude of the marble sand making machine will be caused by long-term wear and tear, overfeeding, or the presence of high-hardness foreign objects in the feed material. When this occurs, it is essential to replace vulnerable parts in a timely manner, reduce the particle size of the feed material, and strictly control the feeding process to ensure that no high-hardness foreign objects are present during feeding.

2. The particle size of the finished sand is relatively large. The main reason for the excessively coarse particle size of the finished sand processed by the marble sand making machine is the looseness of the V-belts. In this case, the V-belts should be tightened in a timely manner; the wear of the internal screen mesh of the marble sand making machine can also lead to the oversized particle size of the finished marble sand. At this point, the screen mesh should be replaced promptly, and attention should be paid to checking the wear condition of the screen mesh before each operation. 3. Excessive bearing overheating During the operation of the marble sand making machine, bearing overheating may occur. The main cause is related to lubrication: first, check whether the lubrication is in good condition and inspect the bearings for impurities. If impurities are found, clean the bearings promptly. Long-term wear can also lead to bearing overheating. If bearing wear is detected, repair the bearings in a timely manner; if the wear is severe, replace the bearings promptly. |