|

|

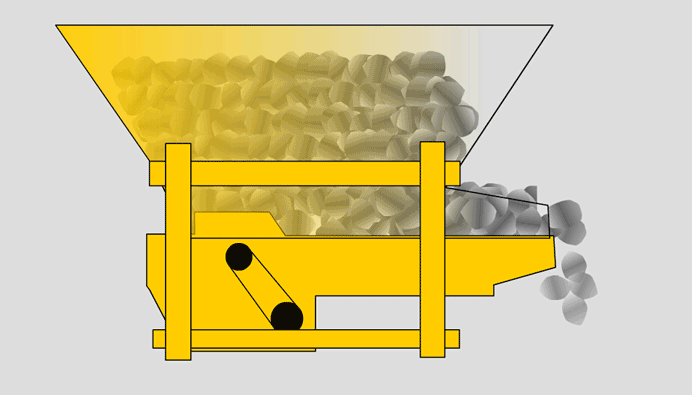

Here are the solutions to some common faults that may occur during the use of vibrating feedersVibrating feeders, apart from crushers and sand making machines, are commonly used ore processing mechanical equipment in sand and gravel production lines. Qidong Zhuoya Mining Machinery would like to remind everyone that vibrating feeders will inevitably encounter various problems during production. Today, let's talk about how to solve these problems.

Blockage of the vibration gap between the exciter core and the armature in the vibrating feeder£º

Fault phenomenon: During the use of the built - in electromagnetic feeder of the vibrating machine, the power switch of the vibrating feeder may trip. After re - energizing, when the feeder is in operation, the fuse may heat up, the current exceeds the standard, and the fuse will blow within a short period. When checking the feeder control system, the contactor suction and other components are normal, but the power switch still trips frequently, and the amplitude of the vibrating feeder is basically zero during operation.

Fault analysis: Based on the phenomenon, the main reason is that materials enter the inside of the exciter, causing the vibration gap of the exciter to be blocked. If the sealing cover is opened for inspection, it will be found that the sealing silicone rubber is damaged. Sometimes, the damage of the exciter cooling hose can also lead to this problem.

Leakage of the outer casing of the vibrating feeder£º

Fault analysis: The sealed casing of the built - in vibrating feeder of the vibrating machine has many connecting bolts. Especially after disassembly and maintenance, it is difficult to achieve a good seal.

Fault solution suggestions: Generally, this problem can be solved by tightening the bolts and adjusting the pressure at the discharge port.

Damage to the exciter bearings

Fault analysis: During the use of the exciter, the bearings may smoke and turn red. Due to the continuous impact on the bearings by the eccentric blocks during rotation and the poor on - site working environment, the service life of the bearings is shorter than the normal service life.

Fault solution suggestions: It is recommended to use bearings of better quality or imported bearings to extend the service life. In addition, bearing lubrication is particularly crucial. Regularly strengthen lubrication or install an automatic lubrication device. |