|

|

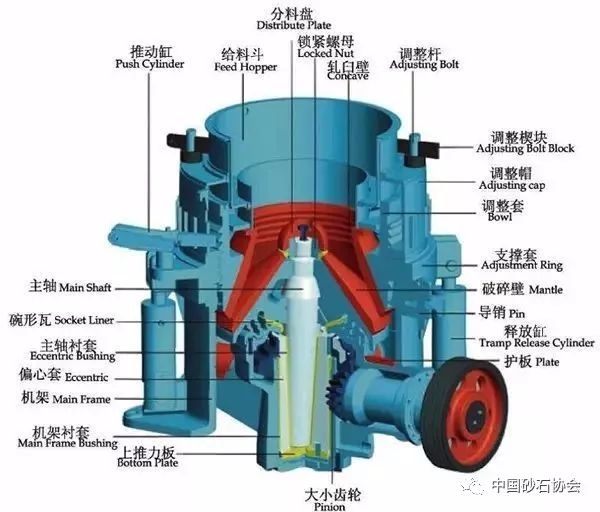

Before starting the cone crusher, inspection work needs to be carried outAs an important crushing equipment in mining machinery, whether it is a newly installed cone crusher or one that has already been in operation, necessary inspection work should be carried out before starting it to ensure smooth operation later.vasoar

First: For a newly installed crusher that has not been tested, before starting it, the equipment should be rotated 2 to 3 revolutions manually or by a crane, and collision accidents should be avoided during this process.vasoar

Second: When there is material in the crushing chamber of the cone crusher, it cannot be started. Once started, it will lead to electrical tripping or damage to the mechanical parts. Therefore, before starting, it is necessary to check whether there is any material in the crushing chamber.vasoar

Third: For a newly installed or overhauled cone crusher, the size of the ore discharge opening needs to be checked and adjusted according to actual needs.vasoar

Fourth: All kinds of electrical interlocking devices, audio signals, etc. need to be checked before starting to see if there is any damage.vasoar

Fifth: Check the oil level and oil temperature in the oil tank of the cone crusher. When the oil temperature is below 20 degrees Celsius, the conditions for starting are not met, and an electric heater, heating water from a heating system, etc. should be used for heating.vasoar

Sixth: Check the oil pressure of the locking cylinder and the adjusting ring. When it is in the locked state, the cone crusher can be started for normal operation.vasoar

|