|

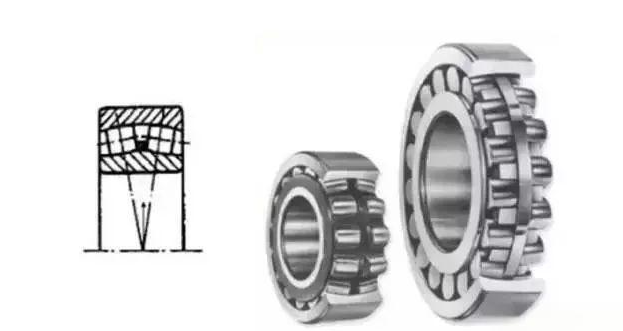

Repair of Bearing Wear in CrusherBearings are an important component in ore crushers, and they are crucial for the machine. Prolonged crushing and processing operations can also lead to bearing wear issues in ore crushers. Today, we will discuss the repair process for shaft wear.

Regarding the wear issue of the crusher shaft, the on-site situation of repairing the wear of the limestone crusher shaft is as follows:

1. Observe the condition of on-site equipment and operating environment, clean up oil and impurities, and measure relevant data;

2. Perform surface oil baking treatment on the worn parts, and then polish off the surface oxide layer and high points;

3. Clean the surface to be repaired with anhydrous ethanol and let it dry for later use;

4. Apply SD7000 release agent to the reference position on the axis and the areas that require protection;

5. Mix the Sorel carbon nanopolymer material proportionally until it is uniform and color free, and then apply the material to the surface to be repaired;

6. Use a benchmark scraping tool to scrape the material along the axis benchmark to the size, and wait for the material to solidify;

7. After the material solidifies, polish and remove excess material, and then reinstall the components to complete the repair. |